Eliminate Profile Distortion or Corrugation

What was the problem?

Profile Corrugation!

The customer wanted to make this:

But unfortunately, this is what they saw after the first shot.

As you can see, the profile was badly distorted. Several costly trial-and-error iterations would be required to resolve the problem.

What was the root cause?

Unbalanced melt velocity!

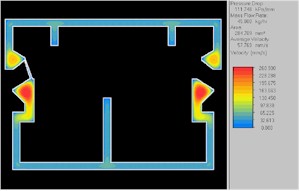

After analysing the die, we found that the velocities in the die were unbalanced. Some sections were moving much faster than the puller speed; some sections were moving much slower than the puller speed. As a result, the faster sections had to slow down, and the slower sections had to speed up. This resulted in the corrugation.

How it was solved?

Balance melt velocity and flow!

We analysed the die using the VEL Profile Die Module and Compuplast's Cross Flow Minimization Method. The die cross-sections were modified so that the flow and volocities were balanced. After the optimized die was bulit, the customer was able to succefully extrude an acceptable profile.

Bottom Line

Normally, it would have taken several trial-and-error steps to obtain an acceptable product (for complex profiles the number of trial-and-error steps is usualy more then 10 without computer optimization). By reducing the number of trial-and-error steps, the customer saved thousands of dollars. The saving is mainly on wasted material, blocking of experimental line from production and being able to deliver the final product faster. The saving on die recuts are negligible with all other expenses (material, time etc.). The die was also more robust - it was less sensitive to changed in processing conditions. The customer was also able to increase the production rate without modifying the die.