Virtual Extrusion Laboratory™ - Flat Spiral Die Module

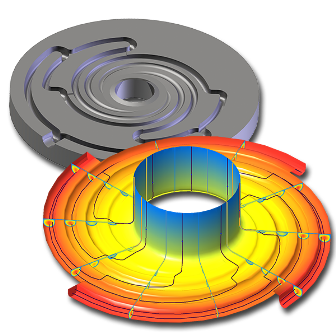

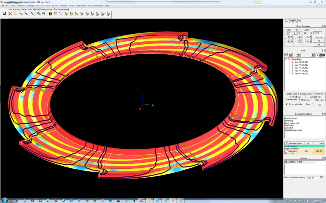

The COMPUPLAST® VEL™, Flat Spiral Die module™ is used for the analysis and design of the types of dies that are typically used in tubular (blown) film production. This module can be used for simulating the flow in flat spiral distribution systems commonly found in “stacked” type of coextrusion dies. The simulation can also include the primary distribution (ports) and also post spiral channels. This module can be easily used for the design and optimization of the flow channel geometry.

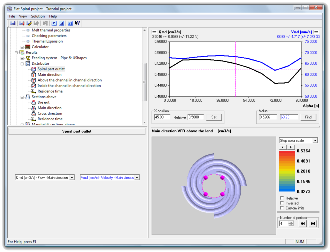

Using the fast, Control Volume Method (CVM) of mathematical analysis, or a fully 3D Finite Element Method (FEM), this module can provide the user with an accurate prediction of the expected die performance.

The parametric geometry editor allows a user to create and optimize a design quickly and efficiently.

Combine it with the Multi-Layer or 2D FEM module and you have all the tools you need to analysis and design annular type multi-layer dies.

The VEL™, Flat Spiral Die module has been developed with the extrusion process engineer in mind. Many world class blown film extrusion die manufacturers use the Flat Spiral Die module as a part of their daily design procedures.

Many processors and technical service personnel use this module to study and analyze the effect of resin changes on their process.

The VEL™, Flat Spiral Die module™ Features Summary:

- Intuitive user-friendly graphical interface

- Fast and easy parametric geometry definition

- Material degradation elimination

- Optical defects elimination

- Analyzing distribution in flat spiral system to deliver even layered coex structure

- Optical defects elimination

- Residence time analysis

- Fast, efficient solvers

- Includes fast CV solvers and also full 3D FEM solver

- Custom report configuration

- HTML report

- Ability to export the results into Excel file

- Powerful post processing