Excessive Screw Discoloration and Wear

What was the problem?

Discolored and scratched screw!

During the routine maintenance, a barrier type, extrusion screw, operating in an extruder barrel with a “grooved” feed section was found to have discolored and the chrome coating on the primary/solids channel had been partially removed.

The above image shows the discoloration and the damaged region on the screw.

What was the root cause?

Improper screw design!

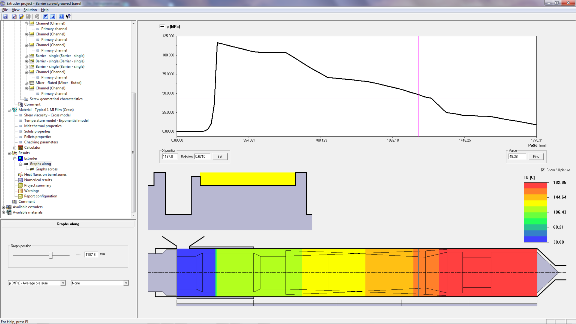

The following image shows the Pressure along the screw, as predicted by the VEL™ Extruder module simulation.

The above image indicates that an extremely high pressure was being created, near the start of the screw, due to a very high amount of material being delivered by the grooved feed section. This resulted and very large forces (pressure and shear stress) acting on the screw surface, and particularly, in the primary/solids channel. These forces were so high that they discolored the screw and, ultimately, eroded the surface.

How it was solved?

An improved screw channel profile design!

Using the VEL™, Extruder module a new, optimized, screw was designed. This new screw had improved melting capability that was balanced with a new feed section that provided a more optimized feed rate so that the pressure and stress values were not as high as in the original screw.

Bottom Line

Simulation of the design, prior to manufacturing the extrusion screw, could have shown the problems with the feeding/melting. The screw design could then be optimized for the required polymer and processing conditions. Improving the screw design could improve product quality, reduce screw (and barrel) wear and increase the production time before the screw needs to be re-built or replaced.