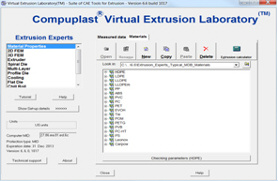

Virtual Extrusion Laboratory™ - Material Properties Module

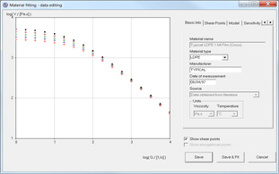

The COMPUPLAST® VEL™, Material Properties module is the main VEL™ module. Material Properties is used to build and maintain a database of materials that can be used for simulation in all of the other VEL™ Modules. It has utilities to fit viscosity versus shear rate data to the available viscosity models and then store the information to the Material Database. The Viscosity Fitting utilities can fit viscosity data to the most popular viscosity models with any necessary corrections. The data can be input by hand, read in from a text file or simply using Windows® “Copy and Paste” functions from a spreadsheet. Once the data have been fit to a model, the program saves the material parameters in the Material Database.

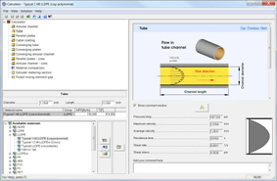

The VEL™, Material module supports all of the other VEL™ simulation modules as a common database for the material properties. In addition to the ability to define and store materials, this module also includes the handy Extrusion Calculator™. The Extrusion Calculator can be used to quickly determine the flow characteristics of some simple, yet common, flow fields. These include flow in tubes, parallel plates, converging tubes, converging plates and parallel or converging annuli. With this feature, the user can quickly judge the size ofadapters and die gaps while also comparing the effect of changing materials and temperature.

The VEL™, Material Properties™ module Major Features Summary:

- Intuitive graphics interface

- Easy material data entry and fitting

- Most useful viscosity model compatibility

- Material database with representative polymer types

- Thermal, viscosity and flow properties available in each material

- Integrated Extrusion Calculator™

- Simple flow field analysis (annular channel, tube, parallel plates, converging tube, converging plates, converging annular channel, coextrusion parallel plates, coextrusion annular channel)

- Material comparison graph

- Extruder metering section analysis

- Fluted mixing element gap analysis

- Image/results saving capability

- HTML report with customized content