COMPUPLAST® Virtual Extrusion Laboratory™ - Extrusion Blow Molding

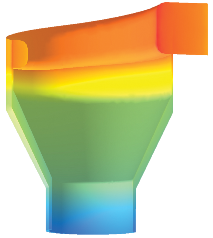

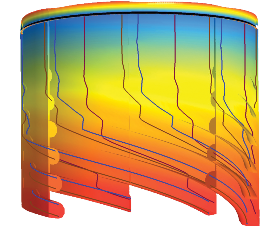

The COMPUPLAST® Virtual Extrusion Laboratory™ for Extrusion Blow Molding can be used to simulate the components of virtually any extrusion blow molding line configuration, including the production of multi-layer parisons, to help troubleshoot and optimize the process. It can be used to study the effect of changes in processing conditions, materials and equipment design.

The COMPUPLAST® Virtual Extrusion Laboratory™ for Extrusion Blow Molding consists of several modules that can be purchased individually, or in combination, to simulate and optimize the various components in a Extrusion Blow Molding Process.

The applicable VEL™ Modules are:

The VEL™ for Extrusion Blow Molding has been developed with the extrusion process engineer in mind.

This Package can be used to help:

- Optimize Die Designs

- Optimize Flow Channel

- Optimize Mono or Coex Die Design

- Optimize Cooling Sections

The versatility and ease of use have truly made the COMPUPLAST™ VEL™ a valuable CAE tool.

The Virtual Extrusion Laboratory™ for Extrusion Blow Molding is also a very useful and powerful product development and process troubleshooting tool.

The modules can be used to help:

- Optimize Material Selection

- Optimize Coex Structures

- Troubleshoot Process Problems

- Minimize Down Time

- Maximize Production