Virtual Extrusion Laboratory™ - Multi-Layer Module

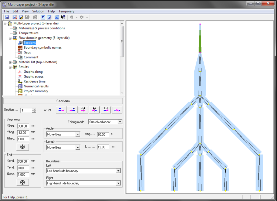

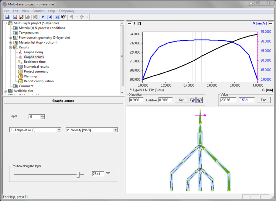

The COMPUPLAST® VEL™, Multi-Layer module™ is used for the analysis and design of multi-layer flow regions in coextrusion dies. Based on the Finite Element Method (FEM) of mathematical analysis, this program can provide the user with a very fast and accurate prediction of the basic flow characteristics needed to design a coextrusion system. Calculation speed is maximized by dividing the flow field into many small sections and performing a 1-D analysis, based on a fully developed flow assumption, in each section. Pressure drops, velocities, shear stresses and interface positions are some of the flow characteristics that are calculated. The user-friendly, intuitive interface and efficient solution technique allows the user to optimize channel designs quickly and easily.

The VEL™, Muti-Layer module has been developed with the extrusion process engineer in mind. Many world class coextrusion die manufacturers use the Multi-Layer module as a part of their daily design procedures. The efficient analysis technique makes it particularly useful for the analysis and design of systems having 3 or more layers. With both planar and annular flow field capability, this module has been successfully applied to the analysis and design of coextrusion dies used in tubular and flat film, sheet, pipe, coating and blow molding applications.

Combined with the Flat Die, Spiral Die or Side Fed Die modules, you have all the tools you need to analysis and design coextrusion dies for almost any application.

The Virtual Extrusion Laboratory™, Multi-Layer module™ Features Summary:

- Intuitive user-friendly graphical interface

- Easy entry of all kind of coextrusion geometries

- Planar or annular flow fields

- Fast and precise solver

- Capability up to 100 layers

- Interfacial instabilities/instabilities in coextrusion

- Material degradation

- Powerful post processing

- Custom report configuration

- HTML report

- Ability to export the results into Excel file

- Applicable for:

- tubes and pipes coextrusion

- flat film coextrusion

- sheet coextrusion

- coating and blow molding