COMPUPLAST® Virtual Extrusion Laboratory™ - Profile Extrusion

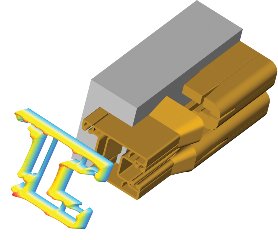

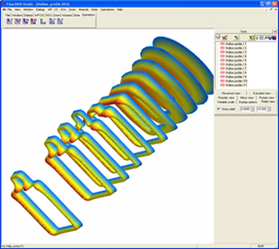

The COMPUPLAST® Profile Extrusion Package™ can help the user visualize the material behavior anywhere inside the process. It also allows for adjustment of the die geometry to get balanced flow inside the die to achieve the desired material distribution at the die exit.

This package can be used for the design and/or optimization of virtually any profile extrusion process including coextruded profiles. It can be used to develop optimized profile dies for maximum production rate, estimate extruder performance and to optimize calibration and cooling systems.

The die flow balancing can be performed either manually or with an optional Automatic Flow Balancing™ feature, which automatically finds the shape of the die

channels that optimizes the material distribution throughout the die.

Experience has proven that a die designed by COMPUPLAST® approach is much less sensitive to variations in process conditions (material lot variations, line speed changes, different extruders etc.) and maximizes the production rate.

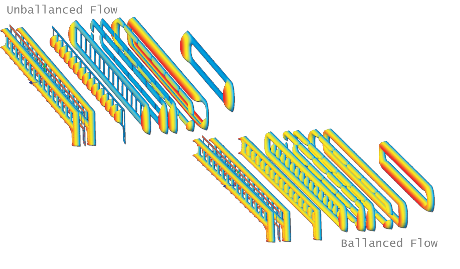

With the Profile Extrusion Package the user can easily avoid the heavily unbalanced flow that occurs during the typical initial die development and thereby achieve the desired profile shape much sooner. Many customers report more than a 50 % reduction in tooling development time.

The COMPUPLAST® Virtual Extrusion Laboratory™ for Profile Extrusion consists of several modules that can be purchased individually, or in combination, to simulate the various components in a Profile Extrusion Process.

The applicable VEL™ Modules in Profile Extrusion Process are:

The VEL™ Profile Extrusion Package can help the user understand/solve the following problems:

- unbalanced flow

- poor surface quality

- poor final thickness distribution

- die sensitivity on process conditions changes

- profile deformation (bending, warping) during cooling

- problems related to the extruder

The Profile Extrusion Package can also show how efficiently and evenly (or unevenly) the profile is cooled and if there is a tendency for bending or warping during cooling.