Eliminate "Unmelts" in Product

What was the problem?

Unmelts in Product!

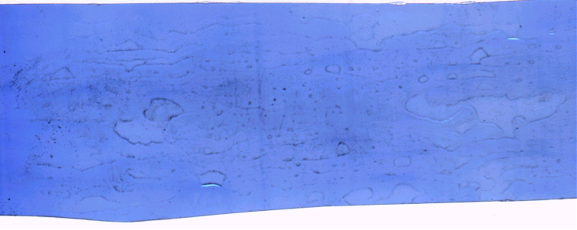

The customer was seeing periodic “showers” of (what they called) “gels” in their extruded film. The line would be running normally, and then suddenly, a “shower” of particles would appear in the film, and then the line would run normally again for a while. The following image is a shows a sample of the film with the defects.

What was the root cause?

The film samples were analyzed and the “gels”/particles were determined to be “un-melts”; non-melted and incompletely mixed resin. The periodic variation suggested that the extruder be investigated.

Solid-bed break up in screw!

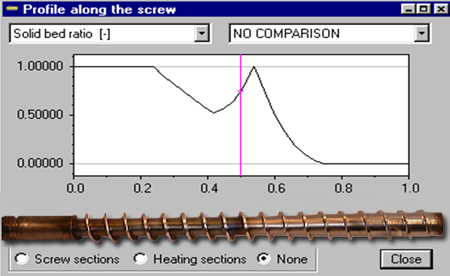

After analysing the extrusion screw, using the VEL™ Extruder module, we found that the compression section was too short. The following image shows a graph of the “Solid Bed Ratio”, along the screw, as predicted by the VEL™ Extruder module.

The above graph indicates that rate of compression was faster than the rate of melting which, often results in “solid-bed breakup”. The rapid increase of the extrusion screw root diameter would result in the solid bed of pellets getting temporarily “stuck” in the compression section where they would spin with the screw. The solid bed/particles would spin in the compression section and would slowly melt until they were sufficiently small to be released and continue down the screw channel. The process then repeats. This condition disrupts the melting process because the solid (un-melted) particles become blended into the melt pool and the pellets do not experience sufficient shear heating or mixing and melt slowly, due to conduction. Since they are not sufficiently blended, they re-appear as they re-crystallize when the film cools.

How it was solved?

Redesign the screw to ensure solid-bed break up does not occur!

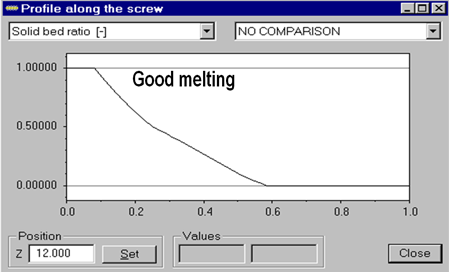

The following image shows the Solid Bed ratio along a new screw design that was optimized using the VEL™ Extruder module.

The screw was optimized so that the solid-bed ratio gradually decrease from 1 to 0, which indicates that solid-bed break up will not occur. After the optimized screw was built and installed, the periodic showers of unmelts were eliminated.

Bottom Line

Normally, it would have taken a long time to simply figure out where the problem was coming from and this would be followed by expensive, and inefficient, “trial and error” modifications to the extrusion screw. Using simulation, we were quickly able to find the root cause of the problem and find a solution much faster. The customer saved thousands of dollars and their scrap rate was significantly reduced.