COMPUPLAST® Virtual Extrusion Laboratory™ - Pipe Extrusion

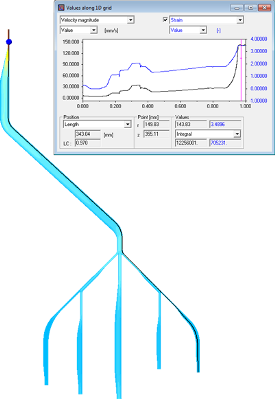

The COMPUPLAST® Pipe Extrusion Package™ can help the user visualize the material behavior anywhere inside the pipe extrusion process. This package can be used to simulate the components of virtually any pipe or tubing extrusion process including coextruded products. It can be used to develop optimized pipe dies for maximum production rate, estimate extruder performance and to optimize calibration and cooling systems.

The COMPUPLAST® Pipe Extrusion Package™ can handle virtually all die

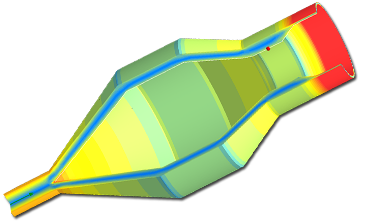

geometries like cross-head/side-fed dies, spiral mandrel dies (flat and cylindrical) and multi-layer dies. The package can be used to evaluate existing equipment or engineer new designs. The results not only include the flow

distribution but also the shear stresses that may result in material stagnation inside the die and/or poor surface

quality at the die exit.

The package can also be used for designing dies with multiple exits like those used for dual wall/corrugated pipes. The package can be applied to both mono-layer and coextrusion processes. As such, problems like interfacial instabilities can also be solved.

The package can also be very useful in solving problems related to cooling; especially for coextruded structures of materials with very different solidification temperatures.

With the Pipe Extrusion Package the user can avoid many problems due to improper equipment design and also reduce the number of physical experiments when developing a new product.

The COMPUPLAST®, Virtual Extrusion Laboratory™ for Pipe Extrusion consists of several modules that can be purchased individually, or in combination, to simulate and optimize the various components in a Pipe Extrusion Process.

The applicable VEL™ Modules for Tube an Pipe Extrusion Process are:

The VEL™ for Pipe Extrusion has been developed with the extrusion process engineer in mind.

This Package can be used to help:

- Optimize Die Designs

- Optimize Flow Channel

- Optimize Mono or Coex Die Design

- Optimize Cooling Sections

The versatility and ease of use have truly made the COMPUPLAST™ VEL™ a valuable CAE tool.

The Virtual Extrusion Laboratory™ for Pipe Extrusion is also a very useful and powerful product development and process troubleshooting tool.

The modules can be used to help:

- Optimize Material Selection

- Optimize CoexStructures

- Troubleshoot Process

- Problems Minimize

- Down Time

Maximize Production

The VEL™ Pipe Extrusion Package can help the user understand/solve the following problems:

- unbalanced/uneven flow at the die exit

- poor surface quality

- material degradation inside the die and slow purging or colorchange

- instabilities in coextrusion

- unbalanced streams in multi-exit dies

- layer pealing and/or forming voids during cooling

- problems related to the extruder performance such as surging, material overheating, material degradation and burning

- insufficient or too rapid cooling