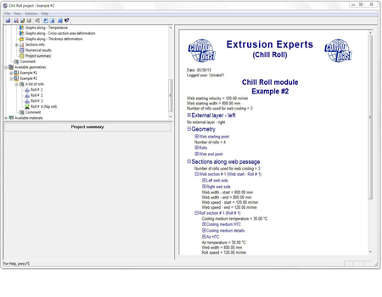

Virtual Extrusion Laboratory™ - Chill Roll Module

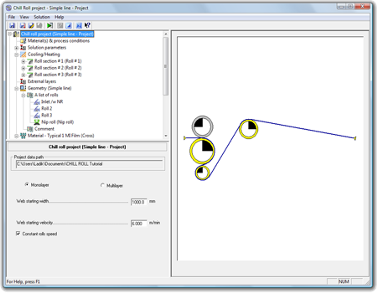

The COMPUPLAST® Virtural Extrusion Laboratory™, Chill Roll module™ simulates the cooling on a chill roll stack of any configuration. The geometry and cooling conditions are easily defined, by the user, with the custom geometry and process editor.

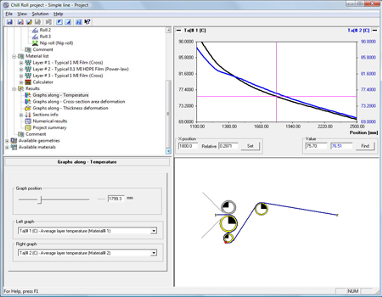

The program provides the temperatures along and through the web.

The web can consist of up to 10 layers including top and bottom substrates such as paper or foil.

The VEL™, Chill Roll module has been developed with the extrusion process engineer in mind.

Many world class extrusion die manufacturers use the VEL™ Chill Roll module as a part of their daily design procedures.

Many processors and technical service personnel use this module to study and analyze the effect of resin changes on their process.

The VEL™, Chill Roll module™ Features Summary:

- Intuitive user-friendly graphical interface

- Fast and easy parametric geometry definition

- Temperature development along each roll surface

- Temperature gradient on the roll body

- Energy transferred between the roll and cooling medium

- Fast, efficient solver

- Custom report configuration

- HTML report

- Ability to export the results into Excel file

- Powerful post processing