Eliminate Degradation in Adaptor

What was the problem?

Material degradation in a Flat die producing PVC sheet!

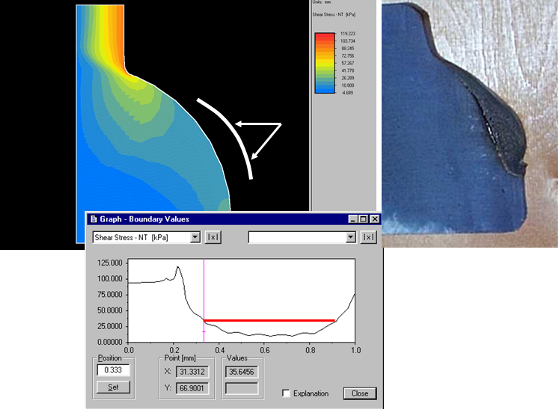

The customer observed black lines on their PVC sheet and upon investigation, it was found that material was degrading in the transition region just after the breaker plate. The following image shows the degradation in the transition region.

The material would stagnate in this region and degrade over time. This problem was so severe that the customer had to stop the line, in order to clean this region, at the end of every shift!

What was the root cause?

Low Shear Stress at the wall!

The image below shows the analysis of this region using the COMPUPLAST® VEL™, 2D FEM module.

The color contours of the shear stress, and the graph showing the shear stress along the wall, indicated that there was a very low shear stress region that coincided with the region where the degradation was occurring. It was determined that the shear stress was not sufficiently high enough to keep the surface “self-cleaning” and this resulted in material stagnation and degradation (build up).

How it was solved?

Increase the shear stress near the walls!

Using the COMPUPLAST® VEL™, 2D FEM module the geometry was modified, and simulated, until the shear stress was above the minimum required value. After the new transition was manufactured and installed, there was no longer any degradation in this region. The customer would only have to stop to perform scheduled maintenance on the die.

Bottom Line

Stopping and starting the line to remove degraded material is prohibitively expensive. It was estimated that the lost production profit was over ½ Million Euros per year! Furthermore, degradation of PVC releases harmful by products which can damage/corrode the equipment and be hazardous to the health of the employees in the plant. Simulation helped to determine the root cause of the problem and find the optimized solution/geometry in less than 2 hours.